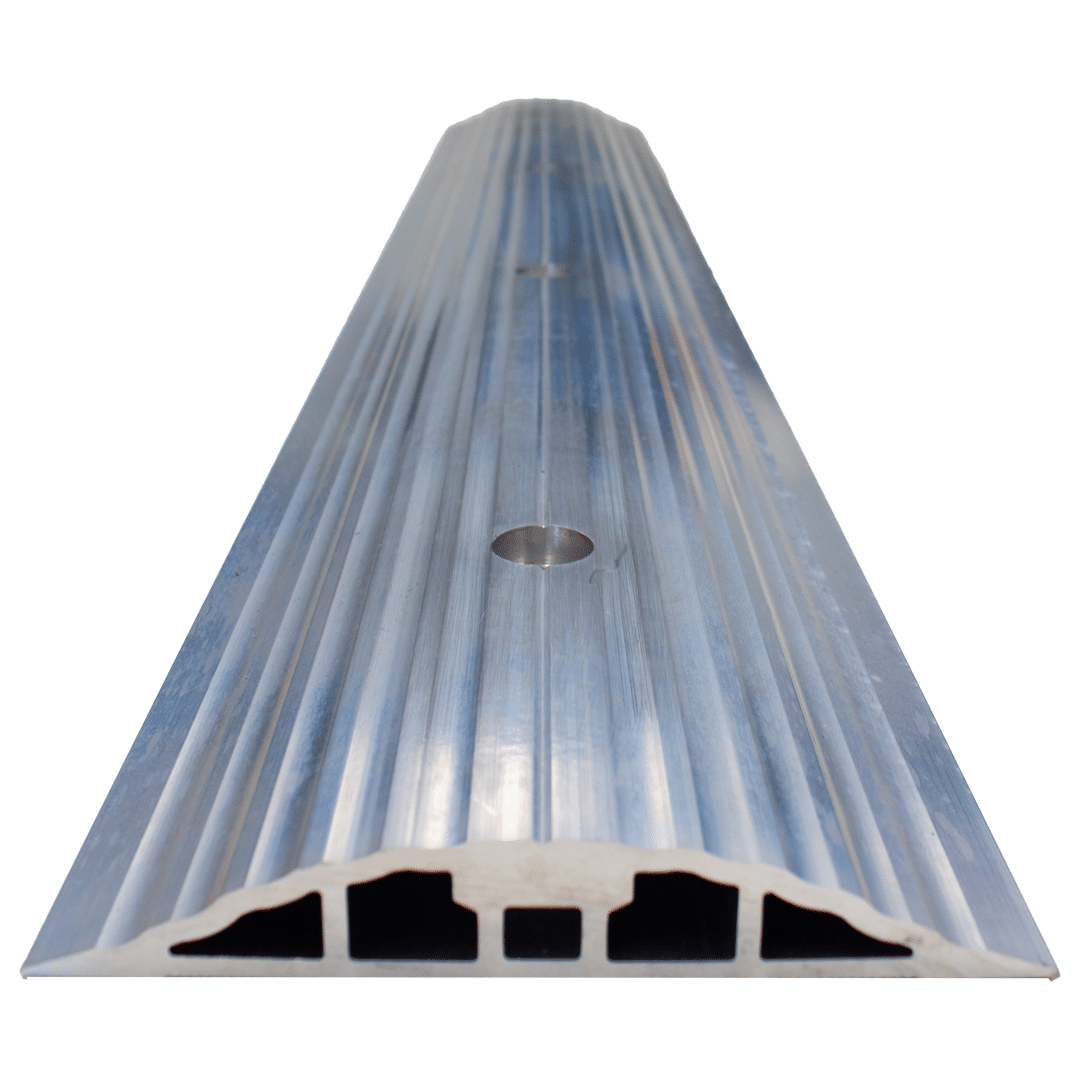

Aluminium Floor Bunding can be retrofitted to quickly and permanently create a compliant bunded area. This solid and robust bund, made from marine grade extruded aluminium, withstands frequent and heavy traffic over a long period of time. The aluminium bund is suitable for heavy vehicles such as Class 2 RAV B-Doubles and heavy-duty container forklifts. This permanent solution offers longevity similar to concrete at a fraction of the price. It is easy to install and can be used indoors or outdoors. The grooved surface assists traction. The low profile allows forklifts to easily pass over without compromising comfort or clearance.

A PERMANENT FLOOR BUND SOLUTION

Aluminium Floor Bunding is suitable for heavy industrial and commercial vehicles. Its fire resistance and ability to accept high load capacity make it ideal for a wide range of sites and applications.

FIRE RESISTANT FLOOR BUNDING

The use of aluminium makes this floor bund ideal for flammable liquid containment as it non-magnetic, non-sparking and is fire resistant. This requirement is stated in the Australian Standard 1940-2004, “A spillage containment compound shall be sufficiently impervious to retain spillage and to enable recovery of any such spillage. The compound shall be chemically resistant and fire resistant as far as is necessary to fulfil its locations.”

Applications

- Industrial areas with heavy-duty machinery

- High-frequency traffic areas

- Class 3 Flammable liquid storage areas

- Liquid storage areas

- Warehouses

- Wash bays

- Fuel depots

- Transport truck parking facilities

Installation

Before purchasing floor bunding ensure you check ground clearance of forklifts. Installation is straightforward. The process requires minimal experience.’

- Ensure the surface under the floor bunding is appropriate

- Clean the surface so it’s free of anything that could affect adhesion

- Layout your bunding to determine you have enough materials

- Cut lengths as required to custom-fit your layout

- Layout the bunding using a chalk line and leave a 2-3mm gap in between lengths (for expansion)

- Pre-drill holes for the concrete fasteners

- Vacuum away the dust

- (optional) Apply sealant to the bottom of the floor bunding and adhere to the ground surface

- Insert the concrete screws

- Once the lengths are installed, run a bead of sealant along both sides where it meets the ground and in the gap between the lengths

- Allow the sealant to cure before using the bunding

Accessories and Options

ONE LENGTH

- CHAFB1

- Length: 1.2m

- Width: 184mm

- Height: 30mm

- Weight: 7kg

- 4 x predrilled holes

INSTALLATION KIT

One tube of adhesive sealant suitable to install 1 length of predrilled Aluminium Floor Bunding

- CHGA1

- Sealant

HI VIS YELLOW POWDER COATING

Full coverage yellow powder coating for high visibility. Suitable for outdoor use.

- CHAFB04

- Minimum of 15 lengths per order.

CUTTING FOR MITRE CORNERS AND CUSTOM LENGTHS

Cutting to create custom lengths and mitre corners.

- CHAFB03

- Drawings to be provided by client before cutting.

- (Outside of these angles, additional charges will apply)

HIGH VISIBILITY YELLOW

Aluminium Floor Bunding can be powder coated to create an extremely tough, heavy duty high visibility option required by some workplaces.

Videos

Aluminium Floor Bunding Intro

Installation

Reviews

There are no reviews yet.